For industrial operations, dependable asset monitoring forms the backbone of efficient management. Selecting a robust IoT data tracking system allows facilities to monitor equipment location, status, and utilization with precision. Wireless sensor networks, when implemented, offer location and environmental data, enabling operators to make well-informed decisions about resource distribution and take timely action in the face of risks like theft.

One approach leverages Trusted, which delivers a comprehensive solution for global asset monitoring and environmental tracking. Features include customizable data collection and global connectivity, supporting efficient reporting and in-depth analysis to drive operational effectiveness.

As organizations look for greater efficiency and a clear overview of daily operations, IoT-based asset management offers systematic improvements in oversight.

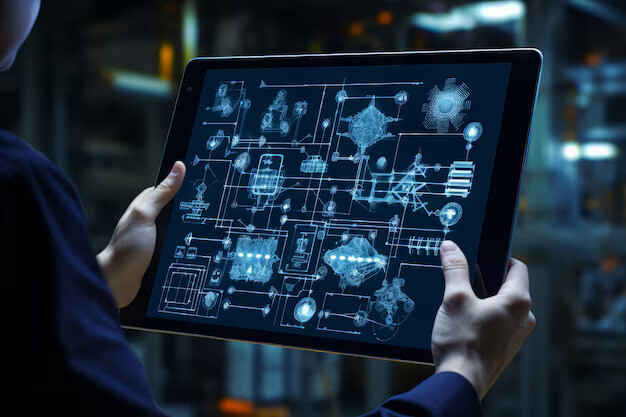

Overview of Wireless IoT Solutions

Wireless IoT offerings use purpose-built sensors to gather essential operational data from industrial assets all over the world. Integrating such IoT solutions offers facilities the ability to enhance protection against security threats, improve operational workflows, and support various sustainability goals as activities expand.

Robust Data Tracking Features

These systems capture and provide a continuous stream of critical metrics—location, real-time operational status, and environmental readings such as temperature or humidity. Alerts signal any divergence from normal ranges, providing rapid notification for prompt action if equipment faces a fault or leaves predetermined zones.

In addition, flexible reporting tools enable adjustments to meet specific needs, whether focusing on compliance data, performance metrics, or site-by-site analysis. Rather than relying on infrequent manual checks, operators benefit from real-time data to better maintain asset integrity.

Global Connectivity

Wireless asset tracking works internationally, facilitated by systems capable of using cellular, satellite, or hybrid methods to relay data. Regardless of site location, asset information remains accessible through cloud-based dashboards, making it possible to track movement across countries or remote installations.

Integration with existing digital infrastructure simplifies oversight. Managers gain a unified platform for monitoring asset status, scheduling maintenance, and reacting to real-world changes quickly, even across geographically dispersed operations.

Key Applications for Industrial Monitoring

Harnessing wireless IoT tracking provides persistent oversight and security for assets. Common applications encompass location tracking, theft prevention, usage analysis, and ongoing support for environmental initiatives.

Asset Monitoring for Industrial Equipment

Accurate asset tracking in industry means knowing where important equipment is at all times, coupled with a steady flow of operational information. Smart sensors report on usage hours, temperature, and maintenance needs, giving managers a clear overview from a centralized dashboard.

Custom parameters allow reporting to align with unique equipment requirements or operational goals. Automated logs boost transparency and lessen manual recordkeeping while increasing resilience against equipment loss or downtime.

Theft Prevention

Maintaining control over high-value machinery and materials is a priority in industrial contexts. IoT trackers mark asset locations, respond to unplanned movement, and relay alerts if items exit defined zones.

If tampering is detected, notifications are generated, enabling immediate measures to secure or recover assets. Historical movement logs help reconstruct incident timelines and inform future security protocols.

Recording Utilization

Tracking when and how assets are being used provides insight into operational efficiency. Detailed logs, including runtime, idle periods, and lifecycle data, enable managers to optimize deployment.

This approach highlights surplus equipment, enabling more strategic distribution and reducing the need for unnecessary acquisitions. Maintenance schedules become data-driven, resulting in fewer unexpected failures and improved resource allocation.

Condition Monitoring

Continuous monitoring of environmental and usage conditions ensures that assets operate within safe and optimal ranges. Sensors track parameters such as humidity, vibration, or temperature, and generate alerts if any limit is exceeded.

Comprehensive records contribute to predictive maintenance and support compliance documentation. By analyzing patterns over time, organizations can better anticipate repairs and minimize downtime.

Supporting Sustainability Measures

Ongoing asset data collection promotes environmentally responsible practices. Sensors record energy consumption and emissions, providing the data needed to assess and adjust resource usage.

With automated updates, compliance becomes simpler, and opportunities to minimize waste or energy draw are more easily identified. This facilitates ongoing improvement in line with sustainability targets.

Customizable IoT Asset Tracking

Flexible IoT systems cater to distinct monitoring requirements, offering tailored options for reporting, analysis, and integration.

Adaptable Plans and Reporting

Customization ranges from straightforward usage reporting to extensive, site-wide environmental analytics. Operators choose sensor types and set reporting schedules, ensuring that the information supports operational objectives.

User-friendly dashboards display data clearly, and reports can be exported for sharing or compliance needs. A single connected platform streamlines access, coordination, and oversight, accommodating evolving organizational demands for industrial asset management.